Effective Cost Management Strategies for Manufacturing

Chosen theme: Effective Cost Management Strategies for Manufacturing. This is your practical, people-first guide to uncovering hidden costs, sharpening operations, and building a culture where every decision improves margins without sacrificing quality. Join the conversation, share your challenges, and subscribe for hands-on playbooks that help teams turn ideas into measurable savings.

Map Your True Cost Structure

Move beyond averages. Trace costs to activities like machine setups, material movements, and quality checks. When electricity, rework, and changeovers are allocated accurately, pricing improves, profitability by SKU becomes clear, and teams target the right improvements without guesswork or finger-pointing.

Lean Waste Removal that Sticks

Value Stream Mapping to reveal end-to-end flow

Walk the product path from order to shipment. Document queue times, handoffs, and rework circles. When everyone sees the same map, cross-functional fixes emerge naturally—fewer expedites, smoother scheduling, and clearer bottlenecks that can be attacked with disciplined experiments rather than broad, disruptive overhauls.

Decompose price into materials, labor, overhead, tooling, and margin. Benchmark scrap, yields, and cycle times. When suppliers see a fair, data-backed model, conversations shift from discounts to joint waste removal. The result is sustainable savings that outlast volatile markets and build mutual trust over multiple sourcing cycles.

Blend dual sourcing, regional diversification, and hedging for volatile inputs. Track Purchase Price Variance alongside total landed cost. Escalate early when deviations appear, and tie corrective actions to owners. A simple risk heat map helps leadership approve protective moves before disruptions become expensive firefighting exercises.

Invite suppliers to co-design for manufacturability, explore alternative grades, and pilot consignment or vendor-managed inventory. One metal fab saved 7% by redesigning brackets for laser nesting efficiency. Share a drawing you suspect is over-engineered—we will highlight common features that quietly inflate cost without improving performance.

Energy, Maintenance, and Asset Efficiency

Install sub-meters on compressed air, ovens, and chillers. Nighttime base-load checks quickly reveal silent waste from leaks and idle machines. A plastics plant reduced energy intensity 12% by fixing air leaks and tweaking dryer settings, paying back sensors in two months and improving product consistency simultaneously.

Energy, Maintenance, and Asset Efficiency

Empower operators to perform basic care, then layer vibration and temperature sensors on critical assets. Predictive signals reduce unplanned stops and overtime. Track mean time between failures and maintenance cost per hour. When uptime rises, unit costs fall without squeezing labor, creating durable savings and calmer production schedules.

Data, Analytics, and Industry 4.0 Visibility

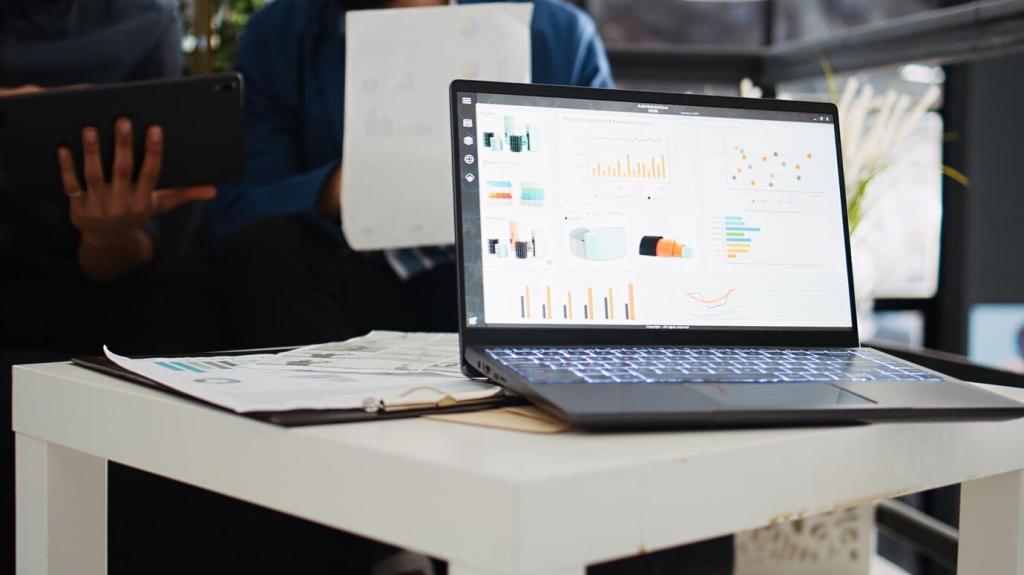

Consolidate ERP, MES, and quality data into a single view that refreshes hourly. Show material usage variance, scrap, overtime, and changeover minutes on one page. When people see the same truth, debates shrink and experiments accelerate, turning meetings from status updates into decision-making sessions that actually move margins.

Data, Analytics, and Industry 4.0 Visibility

Model run-rate changes, labor shifts, and tooling investments before committing capital. A simple twin can test batch-size reductions or alternative routings. One electronics assembler prevented a costly machine purchase by simulating a scheduling change that delivered the same throughput at a fraction of the expected expense.