Streamlining Manufacturing Processes through Consultancy

Selected theme: Streamlining Manufacturing Processes through Consultancy. Welcome to a space where factories become faster, smarter, and calmer. We share practical insights, stories from the floor, and field-tested methods that reduce waste without reducing people. Explore, ask questions, and subscribe to follow every new lesson from the line.

Lean Principles, Tailored—Not Textbook

We balance takt time against setup effort and demand volatility. Smaller batches reduce lead time, but only when changeovers are predictable and material staging is boringly reliable every single shift.

People, Culture, and Change That Sticks

Frontline Champions as Co-Designers

We tap respected operators to trial new routines and document what actually works. Their credibility melts skepticism, and feedback cycles turn experiments into standards that everyone can trust.

Psychological Safety on the Line

When reporting a defect feels safe, quality skyrockets. We coach supervisors to praise early detection, not late heroics, making problems visible sooner and cheaper to solve.

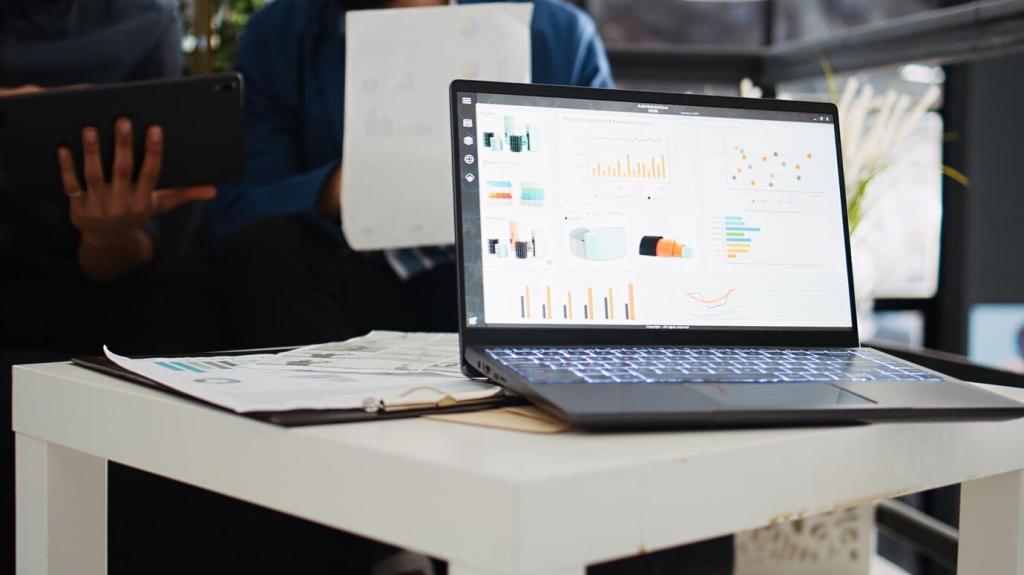

Digital Enablement and Smart Automation

We fix the flow manually first, then automate the proven steps. This avoids encoding waste into code and ensures technology supports a process that already works reliably.

Digital Enablement and Smart Automation

Simple forms capture scrap reasons, trigger Andon alerts, and create maintenance tickets automatically. Deployment takes weeks, not quarters, and the shop floor helps refine every field.

Sustainable Throughput and Resilience

Separate internal and external setup work, stage tools, and use color-coded clamps. Predictable changeovers unlock smaller lots, smoother flow, and a production schedule that finally stays believable.

Operators perform daily care, sensors watch vibration and temperature, and planners schedule interventions before failure windows. Downtime shrinks, and energy use declines as machines run within sweet spots.

We model demand spikes, supplier delays, and staffing gaps, then pre-build playbooks. When disruption hits, teams execute calmly, protecting customers and morale without midnight scrambles.

Your Turn: Share, Subscribe, and Shape the Next Improvement

Drop a comment describing a stubborn constraint, like tool change choreography or inspection queues. We’ll feature real reader scenarios and walk through practical, respectful fixes that teams can try next week.